If you would like to have a new weight bench, but you do not want to spend too much money, then you may want to consider making it yourself. You can make a multi-position flat/incline bench using a 4×4 post a base.

You must remember that the dimensions of this weight bench won’t be suitable for everyone, the height of the person will depend on it. The bench will be around 3.75 feet long, which is an average size.

NOTE: This is not designed for people who are looking for serious weight lifting.

MATERIALS YOU NEED:

- 4 ft. of 3 / 4 × 12 pieces of plywood or solid wood

- 3 ft of 1 × 2 wood

- 8 ft of 2 × 2 wood

- 8 ft of 4 × 4 wood post ● 1 (#10) 8” nut and bolt

- 2 (#8) 3” nut and bolt

- 1 (#10) 12” bolt/screw and 4 bolt nuts

- 8 (#10) nylon washers

- 14 (#10) flat washers

- 4-3 inch long lag screws

- 4 rubber or rubberized feet

- some nails and wood glue

- wood stain and polyurethane protective sealant (optional)

TOOLS YOU NEED:

- Power drill with drill bits

- Circular saw

- Miter saw (optional)

- Wood chisel

- Sandpaper

- Socket wrench or pliers

- Hammer

STEP #1:

Cut all the wood pieces in the proper lengths.

STEP #2:

If you look at the bench illustration, you can see that a simple dado joint has been used to join the legs and the base of the bench. Use your circular saw to make multiple passes to remove the unneeded part, finish it off using a wood chisel.

STEP #3:

Use the wood glue generously for all the joints and then secure it with a lag screw. To make it flush, countersink the head of the lag screw.

STEP #4:

Now drill a hole through one end of the 2×2 wood, remember that the hole must be big enough to accommodate the #10 bolt, This is going to be used for the adjustable backrest support.

Then drill a hole through the side of the benchtop support.

Use (#10) 8” bolt and nut to fasten the benchtop to the adjustable backrest support. Put a nylon washer between the metal flat washers to reduce the friction to a minimum while operating it.

STEP #5:

Repeat the same thing for the swing arm.

STEP #6:

Using 4 bolt nuts, secure the (#10) 12” bolt at the end of the swingarm.

STEP #7:

Due to the proximity of the 2nd notch to the 1st one, use a small metal L-bracket to give more strength to it.

In the second pic, you can see how it should look like when the adjustable backrest support and swingarm are bolted in place.

STEP #8:

Now fasten the backrest and the bench seat with nails and wood glue. Remove the rough edges with a good sanding.

STEP #9:

Use rubberized feet to prevent the bench from sliding when in use.

STEP #10:

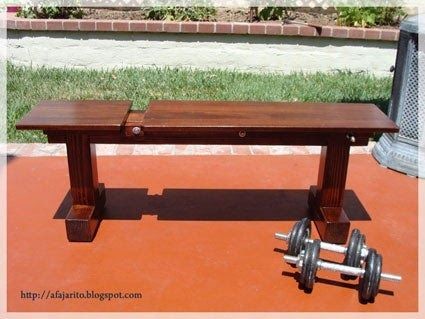

After the finishing touches, this is how it will look like.: